The Corrometer™

The Corrometer™ is a new corrosion "sensor" designed to respond and advise of deterioration in electronic components and other susceptible equipment.The Corrometer™ will let you know when environmental conditions are severe enough to cause corrosion, which is usually the "root cause" for many failures in reliability and asset losses. The Corrometer™ is to corrosion, what the smoke detector is to fire, it will let you know that something needs to be done before the entire asset is lost.

When corrosion occurs we commonly experience it as poor electrical conductivity and it usually means things like batteries are weak which then makes engines difficult to start, or it may increases our power consumption and we see higher bills as a result, or it may slow down your communications and internet speeds. So the bottom line is, corrosion costs you your time or your money or both.

How does the Corrometer™ work?Corrosion is the oxidation process of metals. The Corrometer™ works on the principle that ALL metal oxides (most all non-electrically conductive) increase over time. As the oxide thickness increases it decreases the electrically conductive portion of the base metal. The usual solution to improving conductivity is to replace the part (costly and adds complications), or wire brush or polish away the oxide. The bottom line is; if you want to have excellent electrical reliability, you must have an excellent bare metal-to-metal contact.

The Corrometer™ is able to visually let you how fast that oxide layer is growing. You will be able to measure how well your protection (or no protection) is working, or if it should be increased. Once you know that you will be able to plan and protect your assets from premature depreciation or electrical connections from premature reliability issues and, avoid costly repairs and unplanned service calls.

Your metal and the Corrometer™ corrosion rate will vary depending what the conditions the metal is exposed to, for example desserts are dry and corrosion rates are low, but an island in the ocean has humid air and salt spray which will cause a significant increase in the corrosion rates.

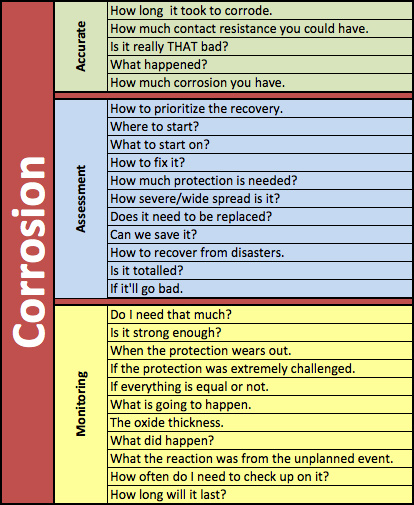

What will the Corrometer™ do for me?The Corrometer™ will do a few things: it can let you know what your corrosion rate is over time, and it can let you know if your protective product, for example, a Corrosion Protective Coating ((CPC) (i.e. WD40, CRC Batter Terminal Protector)), or volatile corrosion inhibitor (A.K.A. VCI), is working by indicating how much corrosion may have occurred.

In short, the Corrometer™ allows you to know what the consequences are to your asset due to what actually happened during its environmental experience, whatever it was, i.e. rain, snow-salt mixtures, spills, increased electrical contact resistance, etc. If you apply a protective coating to your asset, place the same coating across the exposed metal of the Corrometer™ and the Corrometer™ will let you know how effective that coating is, given the environment it is placed. The Corrometer™ goes above and beyond temperature and relative humidity recorders. If a shipment was left out in the rain while going through Customs or sitting on a dock, the Corrometer™ will let you know how the rain impacted your asset.

How does the Corrometer™ Help? / How is the Corrometer™ Used?

How will the Corrometer™ save me money?

When there has been an unintentional disruption in your normal protection like:

- • a break in the protective coating or packaging

- • there was a breach or spill of H2S, SO2, H2SO4, CO2, HCl, water

- • some natural disaster

- • some failure or breakdown in a process or system which caused stuff to leak

You want to know: How much damaged occurred during that unprotected time? Having a Corrometer there while you could not be is your record of how much damage occurred, it allows you to quickly and quantitatively assess the damage to your asset. You can now can make better decisions as to what the recovery plan will be and how to start it.

Placing your Corrometer™.

In a sun shielded location, pick an area representative of the environment you want to monitor; for example, an electrical box or in an inconspicuous area. Then secure the Corrometer™ in place. You may use the two included straps, the double stick tape, or other means to place and secure the Corrometer™.

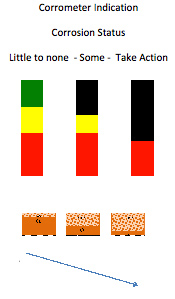

Turning the Corrometer™ "on".For more accurate readings, turn the Corrometer™ on at room temperature 25° C (72° F). If in very hot or cold locations, it is recommended to warm the Corrometer™ before testing. To turn "ON", press the "YELLOW" circle for 1-5 seconds. Once activated, the box above the corroding electrode will display a RED to GREEN color bar, if the entire color bar is GREEN, it indicates there is little to no (0%) corrosion. If the color bar only shows RED, this indicates the maximum amount of corrosion (100%) has occurred and the Corrometer™ has completely corroded.

Determining the corrosion rate.When the color goes from GREEN (0% or no corrosion) to RED (100% or totally corroded), take the number of days it took to corrode and divide by 365.4 days. This gives you the time it took for the Corrometer™ to corrode in terms of a fraction of a year. Once this calculation is made, take that number and divide it into 0.15 µm (0.00000015 meters) or 5.9 µ” (0.0000059”) and this will give you the corrosion rate in µm or µ”/year. Note this is NOT mils/yr (1 mil = 0.001”) So, for example, say it took 200 days for the Corrometer™ to go from GREEN to RED; to calculate the corrosion rate, we first take: 200 ÷ 365.4 = 0.547 Next, you divide time into the thickness. When this is calculated, this will be the corrosion rate per year: .15 µm ÷ 0.547 yr = 0.274 µm/yr or 5.9 µ” ÷ 0.547 yr = 10.78 µ”/yr

| Corrosion Rate (Estimated - Nominal) | |||

|---|---|---|---|

H o u r s D a y s M o n t h s Y e a r s |

|||

| Time | Mils/Year | Microns/Year | |

| 1 | 17.24 | 438 | |

| 3 | 5.7 | 219 | |

| 6 | 2.8 | 73 | |

| 12 | 1.44 | 36.5 | |

| 24 | 0.71 | 4.56 | |

| 2 | 0.35 | 9.125 | |

| 4 | 0.179 | 4.56 | |

| 8 | 0.089 | 2.28 | |

| 16 | 0.044 | 1.14 | |

| 30 | 0.024 | 0.608 | |

| 2 | 0.012 | 0.304 | |

| 3 | 0.008 | 0.203 | |

| 6 | 0.004 | 0.1 | |

| 9 | 0.0026 | 0.067 | |

| 1 | 0.002 | 0.05 | |

| 2 | 0.00098 | 0.025 | |

You may record the installation date and inspection dates on the side of the Corrometer™. If you have a smart phone with a 2D bar code scanning app and an inventory app, you can scan the bar code and log the days using the apps

Don'ts.Although the Corrometer™ has been tested to be compatible with most protective coatings, liquids and vapors, it may not be compatible with strong oxidizers or alkaline substances. It would be best to test for compatibility before using.

IMPORTANT NOTES:

- It has not been tested in areas with explosion potentials, remove device from area before testing.

- It is not intended to be used in areas where temperatures exceed 50° C (122° F) for extended periods of time (+ 4 weeks).

- For determining the most accurate corrosion rate, testing should be done at 25° C (72° F).

- It is not meant to be tested with direct salt spray, unless you are evaluating protective barrier films.

- It is not intended to be in continuous direct sunlight or flames.