Is your most important equipment vulnerable to corrosion?

Is your most important equipment vulnerable to corrosion? Do you have remote equipment locations exposed to the elements?

Do you have remote equipment locations exposed to the elements? Would you prefer to know in advance of unnecessary down time?

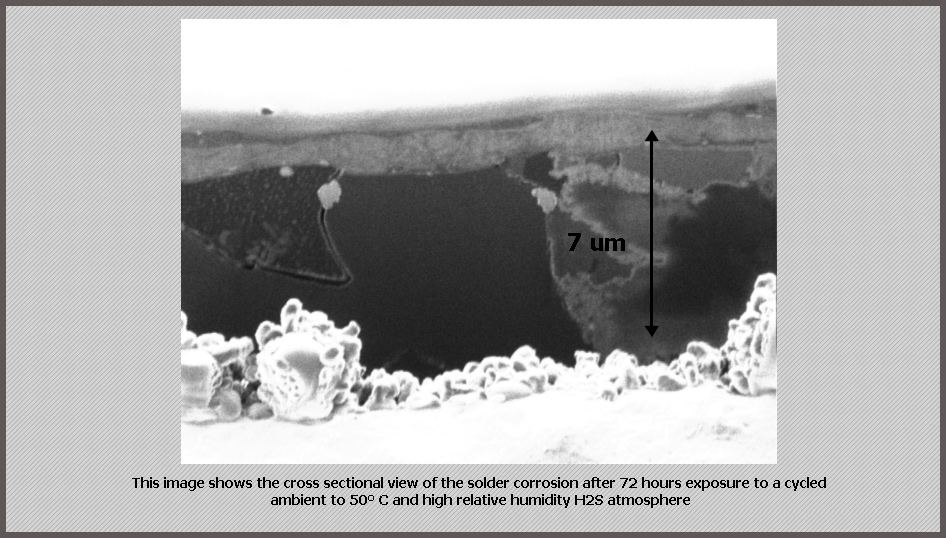

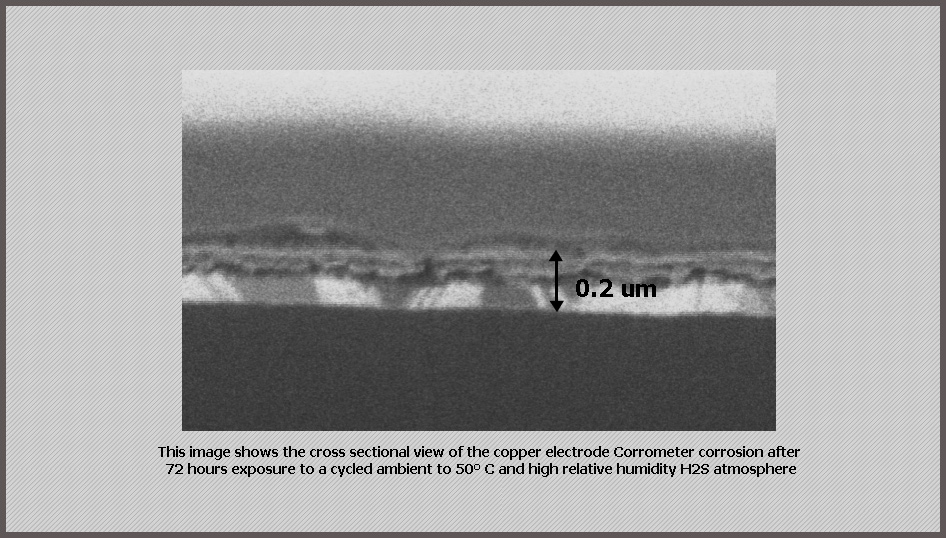

Would you prefer to know in advance of unnecessary down time? Cross Sectional View

Cross Sectional View Cross Sectional View

Cross Sectional View INTRODUCING THE CORROMETER!

INTRODUCING THE CORROMETER!

Corrometer - The Only Visually Indicating Atmospheric Corrosion Sensor

What Is A Corrometer™?

The Corrometer™ is a new corrosion "sensor" designed to respond and advise of deterioration in electronic components and other susceptible equipment.

More

How Is A Corrometer™ Used?

The Corrometer™ can be used to monitor sensitive equipment near reactors, boilers, HVAC and electrical cabinets.

More

How Does It Work?

The sensor’s annunciator is a calibrated sliding scale (0%, no corrosion 100%, totally corroded) display providing early warning before problems arise.

MoreMinnesota CUP 2014 Semifinalist |

||

|

|

Paul Jaeger and the Corrometer have won 2014 Semifinalist Minnesota Cup presented by Dave & Carolyn Cleveland And The Holmes Center For Entrepreneurship.

|

|

Recommended / Alliance Partners |

| Click here if you'd like to learn more about copper corrosion and how much corrosion it takes to have unreliable connections between copper, tin and other conductive interconnects used throughout the world. |

| Click here if you'd like to learn more about corrosion and aircraft. This advisory circular (AC) is a summary of current available data regarding identification and treatment of corrosive attack on aircraft structure and engine materials. |

| Click here for more on the Nace Study "Corrosion Costs and Preventive Strategies in the United States," backed by the U.S. Federal Highway Administration. Estimated annual corrosion costs at the time of $276 billion. |

Field Trials: Corrometer's working in the field.

Traffic signal corrosion monitoring part 1

Corrosion monitoring using Corrometer's, one Corrometer has a corrosion inhibiting film the other does not. We'll see how corrosive the elements like the salty snow and rain are in this unprotected traffic post. Location is Minneapolis MN.

Traffic signal corrosion monitoring part 2

More info on the features of a Corrometer.

Traffic signal corrosion monitoring part 3

Corrometer's at an industrial intersection in Minneapolis MN monitoring corrosion of copper wires in a traffic signal post. One Corrometer is protected with a protective coating the other is not. Corrosion rates reported after 3 weeks in service.

The Corrometer™

The Corrometer™ can reduce costs for replacing parts, unscheduled field service work, warranty claims, packaging verification. It is the ultimate asset surveillance tool so you will know how to properly protect your assets from premature corrosion failures.

The Corrometer™ is an effective and economical way to detect corrosion. Additionally, it is a good indicator to determine that your chosen corrosion protection system is working. The device can show when the environmental conditions are severe enough to cause corrosion, which is the usual "root cause" for failures in reliability and asset losses. The Corrometer™ is to corrosion, what a smoke detector is to fire, it will let you know that something needs to be done before the entire asset is lost.

Contact Info

CONDITIONS MM&D LLC.

Toll Free: 1-866-235-0328

Technical: techserv@corrometer.com

Sales: sales@corrometer.com

Skype: +1 651-300-0508